Suspension design is a very complicated science and usually involves a lot of initial trial and error, before officially releasing it on the market. This explains why the caravan manufacturers have stuck with the basic tried and tested leaf springs setups, for more than 50 years. It was only in the past decade or two that engineers started to think out of the box, and came up with independent suspension designs. These caravan suspension designs are based on the control arm and coil spring setups, that was made popular by the automotive industry.

The basic aim of any suspension design is:

- to absorb the impact of the bump, and minimise force transferred to the caravan body itself

- to effectively dampen the springs natural frequency, so that the natural motion of the spring is not transferred to caravan body during rebound

- to minimize unsprung mass, or the mass of the components not supported by the springs (e.g. axles, suspension arms, wheels, tyres, bearings…etc.)

In this article we will be discussing some of the most common types of suspensions that are available to the Australian consumer today. This article only aims at explaining the differences in the various “types” of suspension, not the various “brands”, so only some of the brand names relevant to the section will be mentioned.

Rigid Axle Caravan Suspension

Fig 1. Rigid Axle

This is the earliest and most basic of suspension designs. Conceived by the automotive industry during its early years, this grandfather of all suspensions has stood the test of time. It is still being used to day in Heavy, Medium and some light duty trucks, SUV’s, vans, buses. Due to its simplicity rigid axle suspensions are also easy to manufacture and install and is usually the standard choice for most on-road caravans on the market today. The rigid beam however means that the motion of the left and right wheels are dependant of each other.

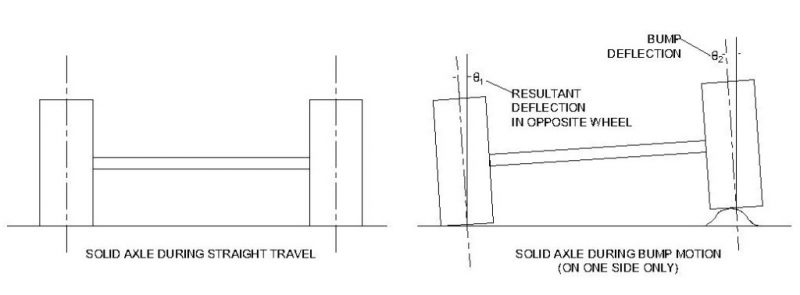

From Fig. 2 above you can see how the bump motion on one side of the axle also results in a deflection of the connected opposite wheel. This translates overall into a more uncomfortable ride.

The axle also add to the unsprung weight of the suspension. With more heavy duty suspensions (1200kg+), the axle beams are made more heavier to handle the load. This also significantly increases their weight. The only thing damping the motion of the unsprung mass is the air within the tyres itself. The large the unsprung mass of a suspension the more it moves when going over a bump. This in turn results in a more “bumpy” ride.

Eye to Slipper and Eye to Eye Leaf Springs

Since the days of the horse-drawn carriages, leaf springs have been used to support axles, and they are still extensively used today more than a century later. The main advantage of a leaf spring is that they are easy to manufacture, and have a high capacity to cost ratio. A leaf spring with the same capacity of a coil spring will only cost half as much as the coil spring would cost. Due to their construction , they also have the advantage of being self-damping, and usually do not require a separate shock absorber to be fitted. Having very few moving components, leaf spring suspensions are also relatively low maintenance. The main complaint is the flattening of the leaves themselves after prolonged usage, which is easily remedied by replacing the leaves, which are not too expensive.

Fig 2. Rigid Axle Bump Motion

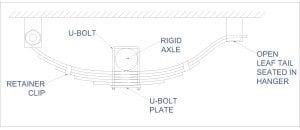

The axle is mounted to the leaf spring via U-bolts. The axle can be mounted either above or below the leaf spring. If the axle is mounted from underneath with the lea spring on top, this is called “overslung spring setup”. Overslung springs give more ground clearance. Overslung springs have less chance of U-bolt failure, since the impact forces are directly transferred to the spring. The main purpose of the U-bolt it to hold the axle in place rather than take impact forces. When the leaf spring is underslung the caravan height is reduced. This is advantageous if you are height conscious of your caravan. Even though the U-bolts are not facing the brunt of the impact forces, most people prefer this setup. The main reason for this is that if the axle or U-bolt fails, there is less chance of the axle going flying down the road.

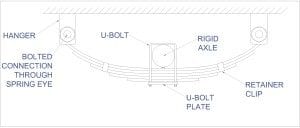

Leaf springs are connected to the caravan via brackets welded to the chassis called “hangers”. Depending on how the leaf springs are connected to the hangers there are generally two types of leaf spring setups.

Eye to Slipper Setup

Fig 3. Underslung and Overslung Leaf Spring setups

In this setup one side of the leaf spring has an loop knows as an eye, and the other end is open. The spring is bolted to the front hanger through the eye. The other end just sits in the hanger. The result is a slipping motion of the springs in the rear hanger during motion – hence the name “slipper”. Slipper springs have less moving parts and as a consequence have less wear and tear and lower maintenance costs compared to other spring setups. For tandem axle setups, slipper springs can be welded as two separate sets of springs. However to maximise sharing of the load among the two axle groups, a Rocker assembly is preferred which combines the two separate assemblies to allow some degree of load sharing.

Eye to Eye or Double-Eye Setup

Fig 4. Eye to Slipper Leaf Spring

When both sides of the spring are bolted via the circular loops, or “eyes” to the hangers – the setup is know as an eye-to-eye leaf spring setup. Due to the stronger bolted connection to the hangers, this setup can support higher loads compared to slipper springs. This setup is more rigid that slipper spring setup. Although it can handle higher loads due to the stronger bolted connections, the rigidity of the setup can cause damage to bearings and leaves over time.

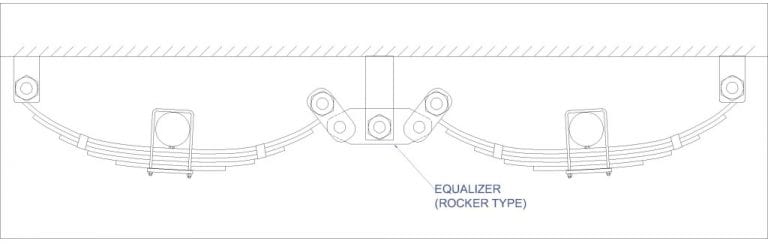

Rocker Leaf Spring (Tandem Only)

Fig 5. Eye to Eye Leaf Spring

The rocker assembly is the cheapest and most common type of tandem axle setup used on caravans. A linkage known as an equalizer “rocks” about its own centre and transfers a percentage of the load from one axle group to another. It is this rocking motion of the equalizer that gives this assembly its common name. By distributing the bump forces and reducing the effective load on each spring the rocker assembly lasts longer than a standard individual leaf spring setup. The equalizer also allows smoother transfer of impact from the leading wheel to the trailing wheel, and thus reduces the forces transferred to the caravan chassis itself.

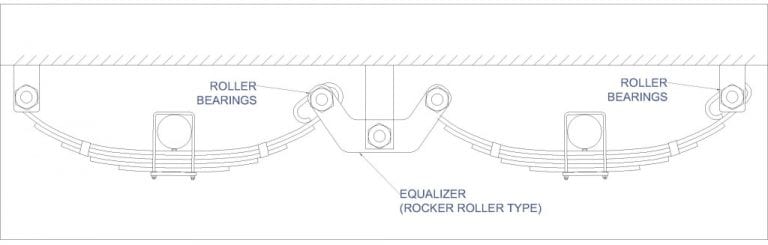

Rocker Roller Leaf Spring (Tandem Only)

Fig 6. Rocker Leaf Spring Assembly

The rocker roller assembly is an improvement over the standard rocker assembly. Two of the bolted connections of a standard rocker setup are replaced with roller bearings. We can now see how the name “rocker-roller” came up. The roller bearings are less rigid and absorb smaller impacts without significant deflection of the leaf spring itself. On larger bump impacts the leaf spring and rocker assembly come into play, just like a standard rocker setup. Since the rollers are less rigid and also absorb some of the impact, this setup lasts longer and has lower maintenance costs than the rocker setup. Due to their lower rigidity it is quite common to find rocker roller suspensions fitted with shock absorbers. The shock absorbers are to mainly dampen the high movement rate of the roller bearings when encountering the small and frequent bumps one encounters on light gravel roads and mild corrugations. These suspensions need to be used with extreme caution on heavily corrugated roads, and are definitely not recommended for off-road use.

Semi-Rigid Axle Caravan Suspension

Semi rigid axles allow some form if independence between the left and right wheels. The torsion beam suspension was used in the famous Volkswagen beetle before the Second World War. Torsion suspensions used on caravans today, are very different to the original torsion beam suspensions used in automobiles. They do not rely on the actual deflection or twist of the metal axle.

Caravan torsional suspensions have an outer main axle that is stationary and is bolted or welded to the chassis. An inner tube is connected to each wheel hub. As the wheels move up and down over bumps, the inner tubes rotates within the outer axle. Sine the inner tubes connected to the left and right wheels are not connected to each other ands move separately, this suspension can be classified as an “independent” suspension.

Caravan torsional axle suspensions are also available in galvanized versions for marine use. They are suitable for mild off-road use and medium corrugations depending on speed travelled. They are not recommended for heavy off-road use and travelling at high speeds over corrugations. Please consult your manufacturer to ensure that your travel plans will not put you in situations that they will not recommend for their fitted suspension. Customers must bear in mind, that a good suspension does not mean that the caravan build quality will be strong enough to handle the vibrations that will be transferred to the caravan body during off-road travel.

Rubber Torsion Axles

In rubber Torsion Axles, the inner tube rotates within the outer tube and is it rotates against rubber tube sections. Rubber being an elastic material acts as a spring and absorbs bump impact when the inner tube rotates against it. Using rubber as a spring to absorb impact has a lot of advantages:

- Rubber has inbuilt damping properties. So the rebound forces are absorbed by the rubber itself and dissipated through the material As susch these suspensions do not need a separate shock absorber

- Rubber has a progressive spring rate. This means that the more deflection it is subjected to the stiffer it gets. Due to this it is very versatile. Rubber can provide soft ride at lower loads, but when the going gets tough, they naturally stiffen up and provide more resistance to impact.

- Rubber provides much better ride than traditional leaf springs, and are fraction of the cost of coil spring trailing arm systems. They are also easy to install, and usually only involve welding the outer axle to hangers connected to the chassis.

Rubber torsional suspensions have less wear due to fewer moving parts, and as a consequence has lower maintenance costs when compared to leaf or coils spring suspensions.

When the rubber loses its elasticity and damping properties due to prolonged or excessive usage, the tubes can usually be replaced by the suspension manufacturer.

Rubber torsion suspension have only recently gained popularity in the Australian market. However they have been extensively used in caravans and motorhomes in the European and American markets for a long time . They are used on extensively on heavy commercial vehicles that transport fragile goods, since they provide a much needed balance between load carrying capacity and ride comfort.

The AL-KO IRS (Independent Rubber Suspension) made and manufactured by European based multinational RV component manufacturer ALKO is the most widely used in the Australian market today. It consists of a hexagonal outer casing with a fluted inner tune that is surrounded by 3 rubber springs. For more information visit – http://www.alko.com.au

American based Axle manufacturer Dexter also have a similar product – Torflex Suspension. It consists of a square outer tube and a square inner rod surrounded by 4 rubber springs. They are available in Australia through Melbourne based distributor Melbourne Trailer and Caravan Supplies –http://www.melbournetrailers.com.au/

Independent Caravan Suspension

Suspensions in which the left and right wheels can move completely independent of each other are classified as independent suspension. Independent suspensions are fairly dear compared to the traditional leaf spring setups. However, they have gained popularity in the past decade with the increasing consumer demand to have a truly off-road caravan, that can handle the unforgiving Australian terrain. Caravan suspensions using coil springs and adjustable air-springs are suitably deemed “off-road”, and they definitely live up to their name.

Simplicity Leaf Spring (Load Sharing)

Designed and manufactured in Australia by N.P Hauffe & Company, the simplicity axle lives up to its name by providing a simple and cheap off-road independent suspension. Since 1955 the company has been engineering transport solutions for the country, from its discreet location in the north of Melbourne.

The axles are connected to pivoting arms that are supported by leaf springs. They come in single and tandem axle version.

Fig 7a. Simplicity Tandem Axle

Fig 7b. Simplicity Single Axle

The tandem axle version of this setup is a true load sharing caravan suspension. The weight acts along the hangers at the midpoint of the suspension, and it is equally distributed to the front and rear axles. This mans there is less chance of uneven wear and tear and the suspension will last longer.

Knee Suspension

Fig 8. Knee Suspension

Created by and used exclusively by Western Australia based caravan manufacturer Coromal Caravans. The knee suspension combines the economical advantages of a leaf spring, and the versatility of an independent suspension in a very unique and distinct way. The suspension is unique in the fact that the control arm, hinges from the centre of the caravan towards the outside. This brings the roll centre of the caravan closer to its centre of mass, resulting in a more stable feel when turning the caravan at high speeds.

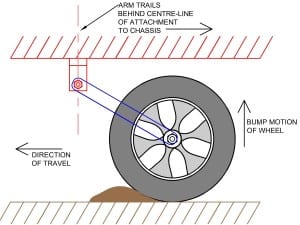

Trailing Arm Caravan Suspension

The most simple forms of independent suspension the trailing arm suspension has proved its excellence in the Australian market. The word “trailing” comes from the fact that the tyre is mounted to the caravan chassis on a trailing mechanical link. This “arm” lies at an angle, behind the connection to the chassis.

Fig 9. Trailing arm Suspension Dynamics

As the caravan moves over bumps on the road the arm pivots about the hanger and moves up and down. By placing a spring between the arm and the chassis in this region we can absorb the impact. A shock absorber is also used to act as a damper, and absorb the rebound forces that cause the spring to have its own up and down motion when compressed. The concept may be simple, however trailing arm suspension design is goes through an intense research process to find the perfect balance between – weight, ride stability and ease of maintenance. There is no point having a titanium alloy arm that will last you 20 years, if you’re going to be spending $15,000 on the suspension alone (although I know a few people wouldn’t mind spending that if it was available).

By using springs with different thicknesses and spring rates manufacturers produce suspension that can handle different amounts of weight. The amount of weight the spring can carry is express in kilograms as a load rating. The load rating is usually the maximum vertical force in kilograms that the suspension is designed to suit. This is usually referred to the GTM (Gross Trailer Mass) of the caravan, since the GTM is the weight of the caravan acting at the axles.

Coil Spring

If a helical spring is used to absorb the impact force, the suspension is known as Coil Spring Trailing Arm Suspension. It is also referred to in short as “Coil Suspension”. All manufacturers have at least one shock absorber connected to the arm to absorb rebound. Most manufacturers provide upgrades to twin shock absorber setups, while some high end suspensions having two shockers as standard.

The most popular suspensions n the market today are :

- Cruisemaster – Made by Australian owned and operated manufacturer Vehicle Components. The Cruisemaster Suspension was one of the first independent suspension to gain huge popularity in the Australian market. They come in two vesions. The cheaper and lighter – CRS (Country Road Suspension) and the premium XT version. The XT version has the option to come with two shock absorbers.

- Control Rider – Made by Australian owned and operated manufacturer GnS Chassis. With over 40 years of experience manufacturing chassis for caravan companies in Victoria, GnS chassis have put their best knowledge and experiences to use when designing the Control Rider suspension. They have a premium high load vesion (4 tonne GTM) called the Control Rider TS.

- AL-KO Enduro Outback– Designed and built in Australia by the Australian division of International RV supergiant AL-KO. After extensive R&D and testing in Australian conditions, modifications have been made to the original European design to better suit the unforgiving Australian outback. The design is lightweight and hence has low unsprung mass.

- Simplicity – Made by Australian owned and operated manufacturer N.P. Hauffe & Company. Going another step further in coil spring design, they have release the first Australian suspension with progressive springs. By designing the springs to have a conical body, the spring rate changes as the spring is compressed. The more the spring is compressed the harder it gets. This allow the spring to stay soft when going over small bumps but stiffen up when going over larger ones.

Airbag

Airbags have now replaced metal coil springs in high end suspensions due to a number of advantages.

- Variable height springs allow caravan to be lowered when travelling on the highway and raised when going offroad.

- When the springs are completely empty the caravan’s height reduces significantly allowing to park in lower roof garages.

- Top end versions have self-levelling electronics that can be useful it there is a slope where parked.

- In case of asymmetric loading of items in caravan (usually kitchen side is heavier with food in the fridge and utensils), airbags one side can be filled with air and made stiffer. This balances the effect of the load on the wheels and prevents the caravan from leaning towards one side.